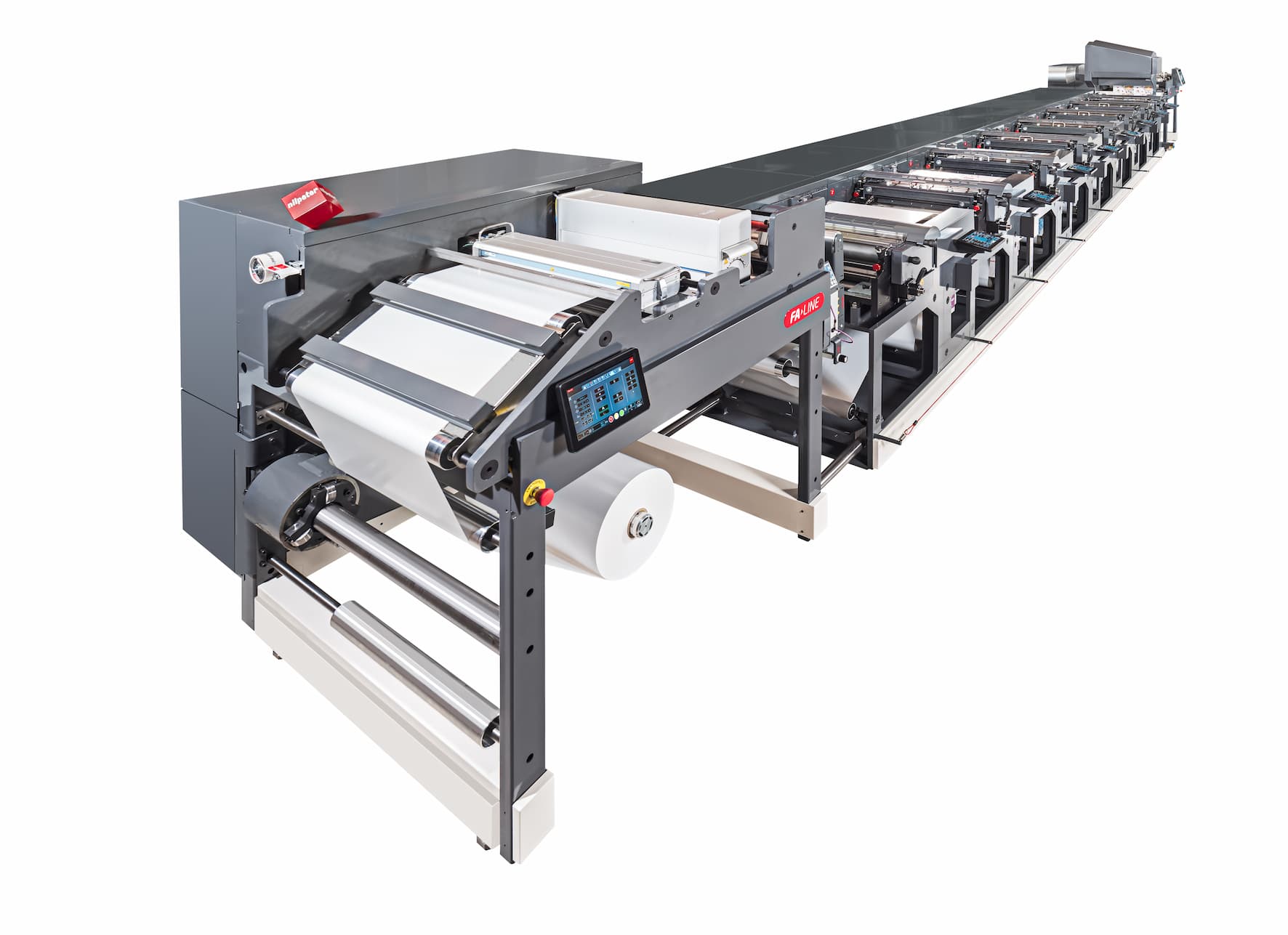

Flexo Line for wider web flexible packaging – All Inline

FA-26 Key features

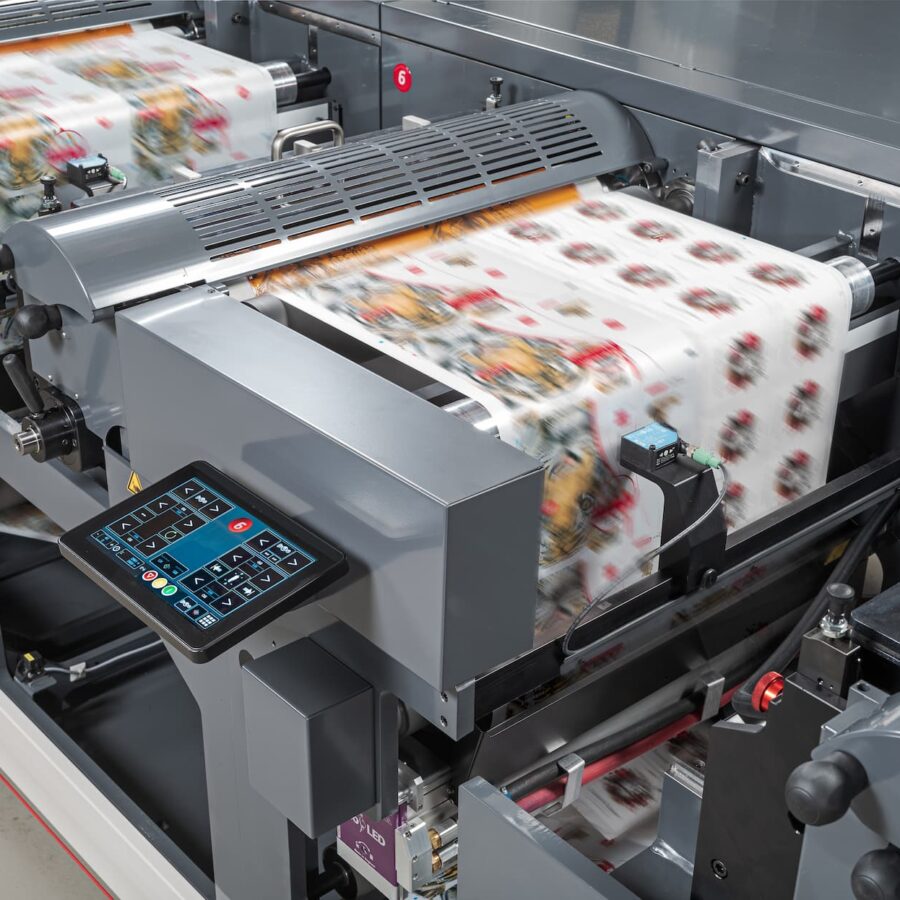

Temperature controlled ink chambers ensuring constant print density

One frame, solid construction, print head landscape design

Sleeve-based print cylinder and anilox roller for slide-in quick change

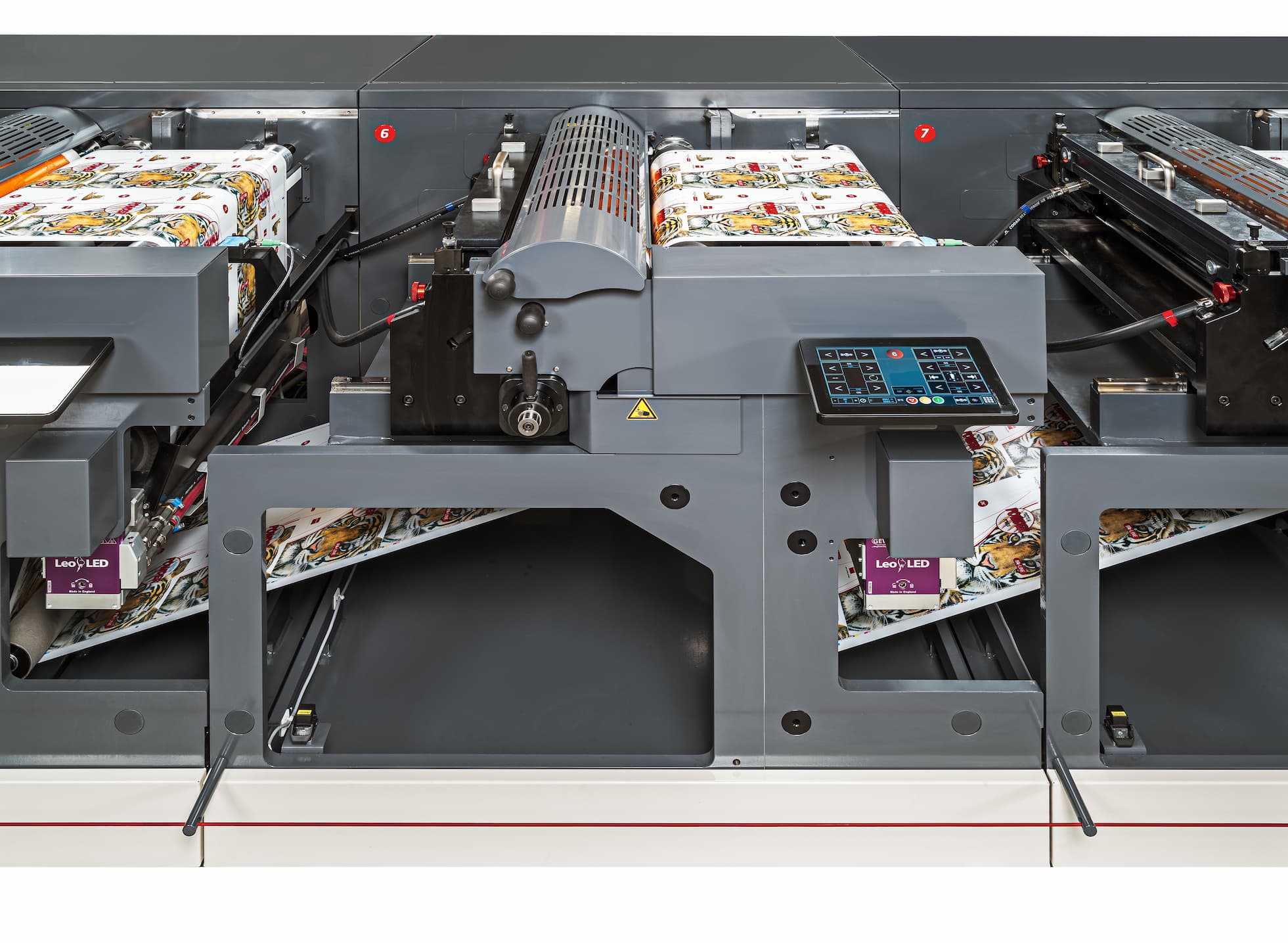

Control panels and main screen for easy operation

Ergonomic and safety focused handling. No manual adjustment needed

Integrated substrate delivery section – including web preparation

Multi flexo abilities – UV/LED, water-based and solvent inks

Temperature controlled ink chambers ensuring constant print density

One frame, solid construction, print head landscape design

Sleeve-based print cylinder and anilox roller for slide-in quick change

Control panels and main screen for easy operation

Ergonomic and safety focused handling. No manual adjustment needed

Integrated substrate delivery section – including web preparation

Multi flexo abilities – UV/LED, water-based and solvent inks

The FA-26 is built for value-added short run flexible packaging and labels. All inline. The robust unit construction, compact footprint, and landscape design ensure optimum register and consistent high print quality at all speeds.

Designed to print with water-based and solvent inks, with UV, LED, and E-beam processes – in any combination, the FA-26 is a game-changer in short run flexible packaging. From pouches and sachets, to wrap-arounds, shrink sleeves, labels, and more.

The FA-26 is fully sleeve-based, both for anilox and plate rollers, with a closed ink chamber system. This construction, combined with the new landscape design, ensures high-quality printing and unique production performance. The FA-26 handles a wide range of flexible substrates, and of course, all standard self-adhesive label materials.

Additional UV-Lamp

Designed to ensure maximum UV-curing before entering the solvent laminating unit. Includes a chill roller under the lamp. Can be installed in any position on the press.

Quick-Change Die-Cutting

For fast job changeovers. Designed to save time on each job-setup, with easy handling of tools, and less material waste.

Hot air dryer

For drying of water-based and solvent inks at high speeds. Dryer position allows for hybrid drying and web temperature management. Can be installed in any position on the press.

Screen printing

Screen printing unit for high-quality special effects, braille, and opaque white. Includes all parts for the screen printing process. Can be installed in any position on the press.

Cold Foil

Includes all parts for adding foil to the printed web, to ensure optimum control of the foiling process. Can be installed in any position on the press.

UV-Lamination

Combined with an optional unwind spindle under the print deck, the UV-lamination unit provides full control of the laminating process and enables curl-free lamination.

Solvent Dry Lamination

Combined with an inline unwind, this unit provides full control , and the best possible results, with lamination of pouches, lidding films, sachets, etc.

Create your own versatility

The FA-26 is prepared for all Nilpeter value-adding units, OEM-auxiliaries, and with multiple drying and curing options. The innovative landscape design enables unmatched customisation opportunities, allowing you to configure the FA-26 to meet varying printing requirements.

With the FA-26 special features, flexible drying, and curing solutions, the printer can pursue new market opportunities in wider web product packaging, while saving tooling costs, production time, and floor space.

Discover the power of the FA-26

Discover the power of the FA-26 for all your Flexible Packaging and Label requirements

Product features

- Pouches

- Lidding

- Wrap-Around

- Shrink

- Form Fill Seal

- Labels

- Sachet

- Tube-laminate

- Flow Pack

- In-Mould

The FA-26 Specifications

Download the brochure

The essential features and overview in one document