Gravure Unit for Metallic Inks, Solids, and Coatings

Gravure Unit Features

This value-adding gravure unit for inline integration offers optimum printing quality with solvent-based inks. It is designed especially for printing metallic inks, opaque white, and special coatings. The unit offers state-of-the-art, inline gravure printing with solvent-based inks, for decorative, technical, and security applications.

An ideal solution

With consistent ink transfer across a wide range of densities, and at high speeds, the unit is suitable for applications, that require a high image quality. Durable printing cylinders make the gravure unit an ideal solution for high quality print on long and repetitive runs.

Features

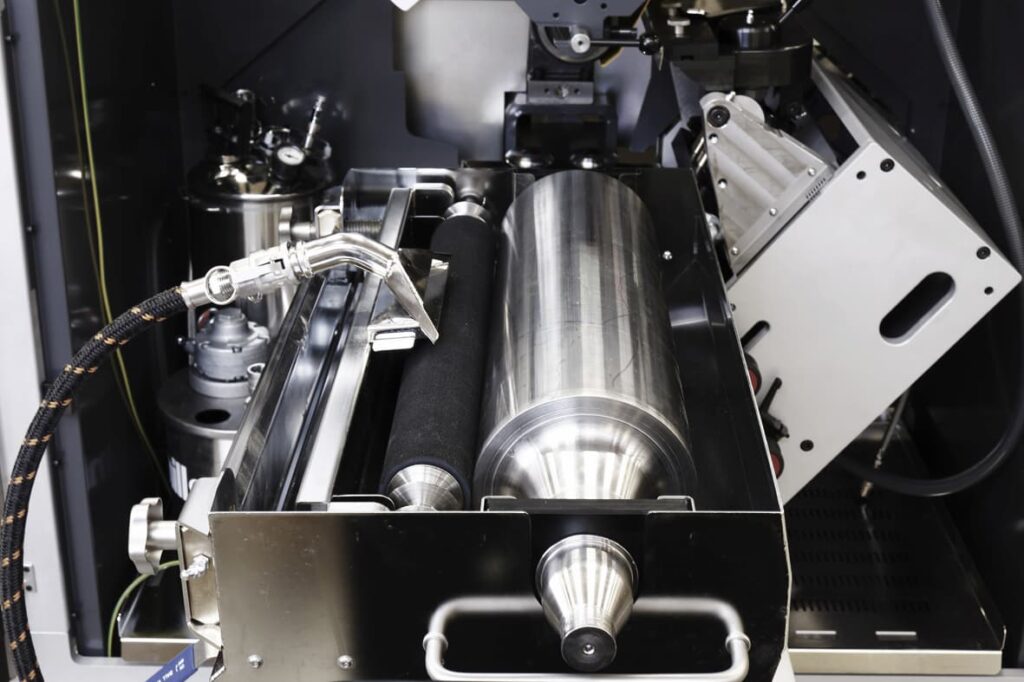

The unit features adjustable doctor blades, ink-circulation system, viscosity control, drying solution, and vacuum systems. Operator safety is ensured by the integrated ventilation system. The versatile solution is prepared for both front and reverse-side printing, and offers quick job change and setup.

Full compatibility

The unit is compatible with all Nilpeter presses and can easily be retrofitted in an existing press configuration.

Features

- Easy-load inner-cassette system

- State-of-the-art inking technology

- Explosion-proof design for solvent inks

- Reversible ink-head for front- or reverse-side printing

- High capacity dryer for high speed converting

Benefits

- Value-adding gravure technology in combination printing

- Designed especially for printing metallic inks, opaque white, and special coatings

- Decorative and security options

- Low material waste

Gravure Unit Specifications

Download the file

The essential features and overview in one document